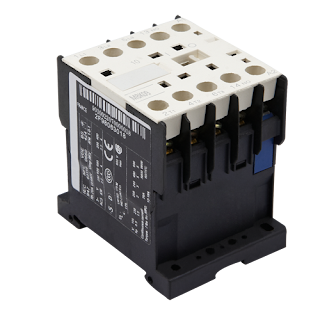

An electrical switching device is an electric contactor. For switching an electrical circuit off and on, it is used. It is a special kind of relay, but between a relay and the contactor, there is a basic difference. In applications where higher current carrying capacity is involved, the contractor is mostly used while for lower current applications, the relays are used. Usually, multiple contacts are featured by these devices. The contacts provide operating power to the load and are mostly normally open whenever the contactor coil is powered. With electric motors, Contactors are popularly used.

There are different contactors types, and their own sets of capabilities, applications and features are present in the various types. Ranging from voltage from 25VDC to thousands of volts and a few to thousands of amperes, Contactors can take over a vast range of currents. Furthermore, in various sizes, these devices come. Measuring up to a meter or a yard on one side, they are small hand-held dimensions to large sizes.

With high-current load, a motor contactor is most commonly used because of its capability to handle high power well over 100kW and current well over 5000 amperes. They produce arcs when heavy motor currents are interrupted. To control and reduce these arcs, a contactor can be used.

Contactor’s Principle of Operation

The contactor’s operating principle is very simple; the electromagnet is energized by the current flowing through the contactor. A magnetic field is created by the energized electromagnet. The contactor core moves the armature as a result of this. Between the fixed and moving contacts, the circuit is then completed by a normally closed (NC) contact. This contact allows the current to pass to the load through the contacts.

The coil opens the circuit and is de-energized when the current is stopped from passing through. The contacts of contactors can close and open rapidly. Thus, larger loads can be handled by them. Moving contacts may bounce as magnetic contactor is designed to rapidly close and open contacts, as they rapidly collide with fixed contacts. In many contractors, Bifurcated contacts are used to avoid bouncing. Follow us on Facebook