Introduction

The

known function of the branch-circuit fuses, circuit breakers, or motor short-circuit

protectors is the protection of the motor and the other branch-circuit

components from higher currents, due to short circuits or grounds.

In

power system loads electrical motors make up a large percentage. One thing that

has compelled the motor control industry to evaluate motor protection

technology continuously is the market demands for reduced downtime and

increased productivity. For motor protection technology advancements now allow

the motor control industry to offer several options. Fuji electronic thermal overload relay are also in high demand.

This

article reviews traditional motor protection technologies and discusses the

new, electronic motor protection options. You should be able to understand the

available technologies after reading this paper and for a given application how

to choose the right solution. In determining the appropriate overload

protection important factors that you need to consider are:

•

Cost per feature

•

To embrace and implement the new technology, the willingness and ability of all

parts of the user’s organization.

•

Application requirements

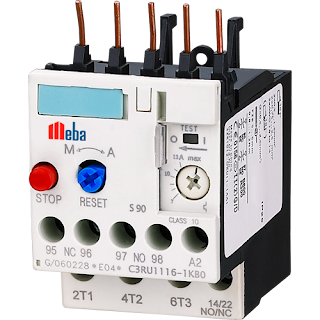

Thermal Overload Relay

In spite of being relatively simple and inexpensive, in providing motor running over current protection thermal overload relays Schneider are very effective. This is possible because winding insulation is the most vulnerable part of most motors and by excessive high temperature this insulation becomes highly susceptible to damage. Being a thermal model of a motor, at a higher current the thermal overload relay will produce a shorter trip time that is very much similar to the way a motor reaches its temperature limit in short span at more current.

Similarly,

a thermal overload relay will trip at a lower current or vice versa in a high

ambient temperature allowing the motor to be used to its maximum capacity in

its particular ambient temperature. In conjunction with a contactor, the electronic thermal overload relay must

be used. There are no power contacts in the overload relay and it cannot

disconnect the motor by itself.